China Bangla Engineering Co., Ltd. (CBECL) is the leader in supply and installation of brick making machine in Bangladesh. We supply clay brick machine from China , India, Italy, etc. Our brick making machines are best in quality for this industry.

If you are looking for the best consultant and company to supply clay brick making machine, fly ash brick making machine or cement brick machine; then, you have already found them.

Auto bricks making plant is popular industry all over the world. The government of Bangladesh has forbidden the zigzag brick fields. The automation of bricks making plants in Bangladesh is mandatory.

CBECL provides turn key solution of automatic bricks manufacturing plants. The standard capacity of auto brick making plant in Bangladesh may be 50000pcs/day, 100000pcs/day, 150000pcs/day, 200000pcs/day.

We have mini auto bricks plant with green technology and low cost machinery too.

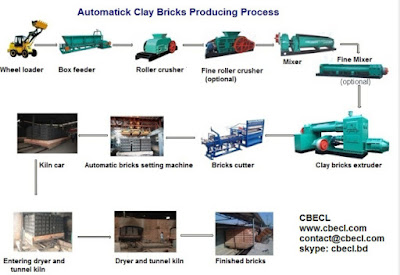

|

| Clay brick production process flow |

We provide consultancy services to design plants, selection of machinery, project profile preparation and availing loan from banks for your auto bricks manufacturing project.

Get loan for auto bricks project:

We work for loan from banks to set up auto bricks manufacturing plant, prepare project profile of auto bricks making plant, supply complete machinery of auto bricks plant, install machinery and provide after sale services. Contact us for detail information.

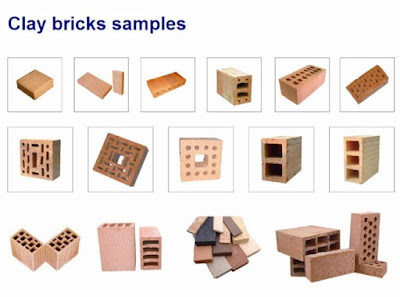

|

| Sample clay bricks |

Guarantee of Lowest Cost for auto bricks plant:

We provide turnkey solution of auto brick production plant at lowest rate. Our expert engineers from China & Bangladesh will set up your plant with proper care and vast experience.

Clay Bricks Production Line of 200,000. Pcs/day

(254mm*127mm*76mm,Tunnel kiln of 160*3.9 meters×2)

A. Clay brick plant data:

1. Plant area: 32000 m² (24 Bigha) or more (about 200 meters length), and we can make design based on your plant size;

2. Construction area: 6800 m² (Including raw materials storage shad, 800 m²; Wet bricks storage shad, 18*120=2160m²; Producing equipments workshop (15*40=600 m²); Tunnel kiln and bricks unloading shad, 15*170=2550 m²; Office building area, 600 m²);

3. Raw materials area: 1200 m²;

4. Finished bricks area: 7000 m²;

5. Raw materials needed per day: 530-550 m³;

6. Workers needed: 30 workers per shift;

7. Producing capacity: 16000-20000 pcs/hour.

8. Raw materials plastic index: 7-17;

9. Moisture content of green brick: 16-18%.

B. Tunnel kiln technical data:

1. Tunnel kiln length: 160 meters×2 tunnel kiln;

2. Tunnel kiln inner width: 3.9 meters;

3. Tunnel kiln Inside Height: 1.56 meters;

4. Kiln car size: 3.6×4.0×0.87 meter;

5. Bricks setting layers in the kiln car: 13 layers

6. Brick setting quantity in the kiln car: 5600 standard bricks;

7. Kiln car quantity in the tunnel kiln: 40;

8. Bricks drying time: 24 hours;

9. Bricks firing time: 42 hours;

10. Firing temperature: 950-1100 ℃;

11. Moisture of green brick: 16-18%;

12. Moisture of bricks after drying: ≤6%;

13. Finished firing bricks ratio: ≥95%;

14. Working time per year: 300 days;

Clay Bricks Production Line of 100,000. Pcs/day

(Tunnel kiln and dryer of 108*3.7 meters)

Size of solid brick: 10x5x3 inches (254x127x76 mm)

A. Clay brick plant data:

1. Plant area: More than 13200 m2 (the length is more than 130 meters, and the width is more than 100 meters. We can made design based on your actual area);

2. Office area: 240 m2.

3. Construction area: 4300 m2;

4. Raw materials area: 1200 m2;

5. Finished bricks area: 4000 m2;

6. Raw materials consumption: 300 m3/day;

7. Workers needed: 20 workers per shift;

B. Tunnel kiln technical data:

1. Tunnel kiln length: 108 meters;

2. Tunnel kiln width: 3.7 meters;

3. Inside Height: 1.56 meters;

4. Kiln car size: 3.6×3.8×0.87 meter;

5. Bricks setting layers in the kiln car: 13 layers

6. Brick setting quantity in the kiln car: 5208 standard bricks (230*115*53 mm);

7. Kiln car quantity in the tunnel kiln: 30;

8. Bricks drying time: 20 hours;

9. Bricks firing time: 42 hours;

10. Firing temperature: 950-1100 ℃;

11. Moisture of green brick: 16-18%;

12. Moisture of bricks after drying: ≤6%;

13. Finished firing bricks ratio: ≥95%;

14. Working time per year: 300 days;

How much coal is needed for firing bricks?

For Bangladesh brick size of 10*5*3 inches, the total coal needed for firing per pcs brick is about 200-250 g (including adding coal inside of the green brick). That is, you will need 20-25 Tons coal for firing 100000 bricks, 40-45 tons for firing 200000 bricks and 10-12tons for firing 50000 bricks.

You can also take biomass briquette (sawdust, rice husk, straw, etc.) as the fuel of Hoffman kiln.

You can also take biomass briquette (sawdust, rice husk, straw, etc.) as the fuel of Hoffman kiln.

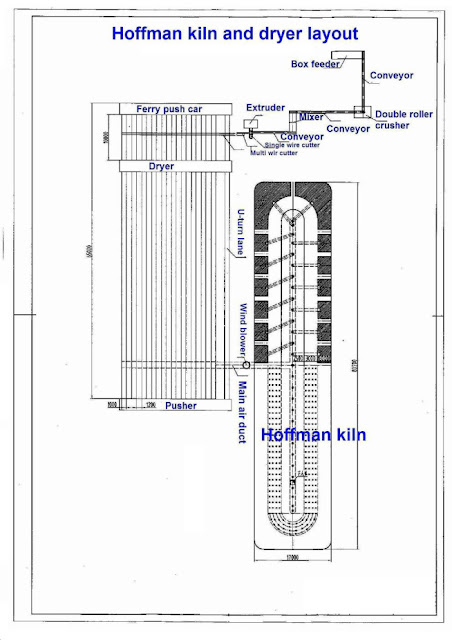

|

| clay brick production Line Layout |

Turnkey Project of Auto Clay Bricks Production Line of 50000 pcs/day

Approximate cost of project: 14,50,000 USD , excluding the cost of land, considering the market of Bangladesh.

The cost of mini auto bricks plant of capacity 40000 pcs per day will be 9,30,00,000 taka to 12,50,00,000 taka for complete machinery, dryer, shed and kiln construction.

| No. | Name | Quantity |

| 01 | Clay brick making machines, Hoffman kiln and dryer | |

| 02 | Customs clearance in Chittagong | |

| 03 | Transportation cost from Chittagong to the brick plant | |

| 04 | Transformer and control box | |

| 05 | Diesel generator (250 KW, Cummins, can be deleted if no need generator) | |

| 06 | Clay brick for construction of hoffman kiln and dryer | 500,000 pcs |

| 07 | Cement construction of hoffman kiln and dryer | 40 MT |

| 08 | Quicklime construction of hoffman kiln and dryer | 10 MT |

| 09 | Wood for construction of hoffman kiln and dryer | 3 cubic meter |

| 10 | Filling clay in the hoffman kiln | 2500 cubic meter |

| 11 | Unearth and smooth project with wheel loader and excavator | |

| 12 | Construction workers’ cost of hoffman kiln (30 chamber) | 1250 USD one chamber based on China’s construction cost (May be lower cost and longer construction time in Bangladesh). You can also calculate the cost based on 30 construction workers for 5 months. |

| 13 | Construction workers’ cost of dryer (10 lines) | |

| 14 | Installation cost of clay brick making machines (Foundation and installation) | |

| 15 | Shad for brick making machines and dryer (Clay brick machines workshop (15*40=600 m2); Dryer shad, 15*20=300 m2.) | 900 square meter, 30 USD/square meter |

| 16 | Light steel house (For commissioning workers housing and office, 3.5*6 meters one house, 10 house) | 210 square meter (can be adjusted), 60 USD/square meter) |

| 17 | Non-expected cost | Based on the 5-8% of the total value. |