Engineering

Industrial Engineering & Consultancy

- Company Documentation

- Project Planning & Design

- Project Profile Preparation

Machinery

Machinery Supply & Installation

- Machinery Sourcing

- Machinery Supply

- Machinery Installation

Construction

Industrial Building Construction

- Site plan and layout

- Drawing & Estimation

- Construction & Supervision

CBECL GROUP is a leading group of companies is Bangladesh providing industrial engineering and construction solution.

CBECL GROUP™ supplies industrial machinery and equipment, provide installation and technical support in the field of rice mill, feed mill, jute mill, flour mill, oil mill, cold storage, auto bricks, concrete block manufacturing, food and beverage production line, water treatment. effluent treatment plant and many other projects.

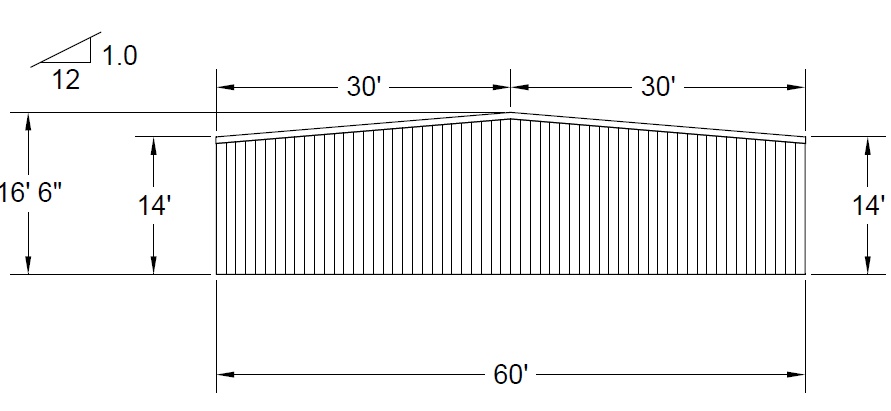

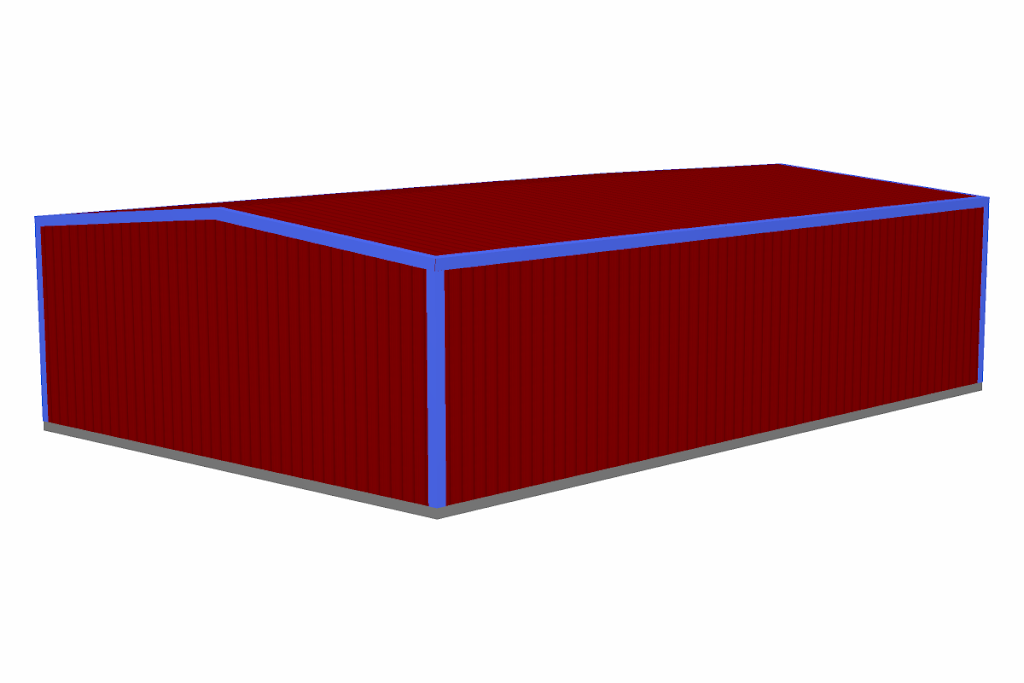

CBECL GROUP™ provide industrial construction services like steel structure factory sheds, warehouse racking solution, industrial plant design and layout preparation, industrial construction supervision and steel building fabrication, erection and maintenance services. We also make commercial and residential building with steel structure.

Industrial Engineering & Construction

Industrial Engineering & Consultancy

We provide Industrial Engineering & Consultancy services in Bangladesh. In this services, company formation nd documentation, industry planning and design, project planning, project profile preparation are included.

- Company formation: We provide RJSC registration services, VAT – TIN registration services, brand trademark registration, board of investment registration services.

- Project planning: We select products that suite your project, fix the capacity of production, the technology of operation as per your requirement of project according to the market demand.

- Project profile preparation: We provide project profile and feasibility report preparation services for investment purpose. We make the project profile according to the standard format prescribed by Bangladesh Bank, so the project profile is accepted by all banks in Bangladesh and invests all around the world.

Machinery Supply & Installation

We source and supply all kinds of industrial machinery to our buyers. We have source of machinery from China, India and Europe. We visit the factories of manufacturers, select the best machinery and supply to our customers. We provide installation of machinery and equipment and after sale services too. Agro based industries, construction based industries, printing and packaging industries and recycling industries are most popular products.

Industrial Building Construction

We provide complete solution of industrial building and factory shed or warehouse construction. We have dedicated team for this. From layout design, estimation of materials, cost analysis, soil analysis, civil design and drawing, construction work supervision, construction materials supply, fabrication, erection and installation to end of project hand over, we work on turn key basis.

Our Specialties

Expert Team ↗

A large and expert team of engineers and technicians is our heart of good quality services.

Long Time Experience ↗

An experience of long time is our root of confidence to provide you the best of market.

Quality & Honesty ↗

No compromise on quality and honesty is our moto in all of services and products.

GET IN TOUCH